2025-12

19MFC & Brain-Computer Interfaces: From Mind Control to Precise Flow.

As clinical trials for invasive brain-computer interfaces (BCIs) continue to advance in China, the related manufacturing processes are gradually evolving into an emerging industry chain. This chain integrates fields such as semiconductors, precision medical devices, and biomaterials, falling within the scope of ultra-high-precision manufacturing. At several key production nodes in this industry chain, the Mass Flow Controller (MFC), as a core component for precisely regulating process gases, plays an indispensable role.

MFCs in the BCI Supply Chain

Node 1: Microfabrication of Neural Probe Chips

The core hardware of BCIs, its manufacturing process is highly similar to that of high-end semiconductor chips. During the process, to protect delicate neural tissues, electrodes often require ultra-thin coatings, placing nearly stringent demands on the control accuracy and stability of MFCs.

· Key Processes: Depositing insulation layers via CVD on silicon or flexible substrates, or plasma etching micrometer-scale electrode trenches and contacts. MFCs are required to precisely control the flow rates of reaction gases (e.g., SiH₄, NH₃, CF₄) and etching gases, with a control accuracy requirement of above ±1% F.S.

Node 2: Device Packaging and Biocompatible Coating

Implantable devices must operate stably long-term in cerebrospinal fluid, which is rich in water and ions. To reduce immune rejection, electrode surfaces often require vapor-deposited biocompatible coatings.

· Hermetic Sealing: When chip modules undergo vacuum or inert gas filling for packaging, MFCs are used to precisely control the gas atmosphere and pressure within the cavity, ensuring zero leakage and protecting the internal circuitry from moisture erosion for its entire lifespan.

· Biocoating Deposition: MFCs accurately and stably control the flow rate of coating monomer gases, ensuring the coating is uniform, pinhole-free, and has controllable thickness. This forms the foundation for guaranteeing biosafety and stable electrochemical performance.

Node 3: R&D and Testing Environment Support

At the laboratory stage, constructing reliable testing environments for cell or animal models also relies on MFCs.

· Cell Culture and In Vitro Testing: When evaluating the biocompatibility of electrode materials or conducting in vitro brain slice electrophysiological experiments, precise control of O₂ and CO₂ concentrations in incubators or perfusion systems is required. By adjusting the proportion of mixed gases, MFCs maintain a highly stable, biomimetic metabolic environment for nerve cells, ensuring the reliability of experimental data.

· YIDU ·

For MFC manufacturers and providers like Yidu, the cutting-edge field of brain-computer interfaces represents not only a high-value-added emerging market but also a touchstone for technological capability. It explicitly demands that MFCs possess:

· Ultimate precision and stability (especially for minute flows);

· Compatibility with special process gases (e.g., silane);

· The ability to integrate seamlessly with automated production equipment and scientific research instruments.

Differential Pressure Laminar Flow MFCs Address Core Challenges

In ultra-precision manufacturing fields like BCIs, the advantages of differential pressure laminar flow MFCs are not merely simple performance parameters; they systematically address the core pain points in production.

The Value of Yidu

· Advantages of Domestic Substitution: Domestic BCI companies are growing rapidly, with strong demands for supply chain security, controllability, and cost. As the currently known sole domestic manufacturer of laminar mass flow meters and controllers certified by the National Institute of Metrology of China, and the world's second high-tech enterprise capable of producing general-purpose laminar mass flow meters, Yidu leverages local service advantages to co-develop customized solutions with these companies.

· "Clean" and "Compatible": Addressing the medical device nature of BCIs, Yidu products differ from ordinary industrial MFCs, having obtained certifications for material biocompatibility and non-contamination. Yidu currently possesses a Class 100 (ISO Class 5) ultra-clean environment room.

· Focus on Breakthroughs in Niche Technologies: Yidu has a mature product system for micro gas flow control, with key metrics meeting or surpassing those of international competitors.

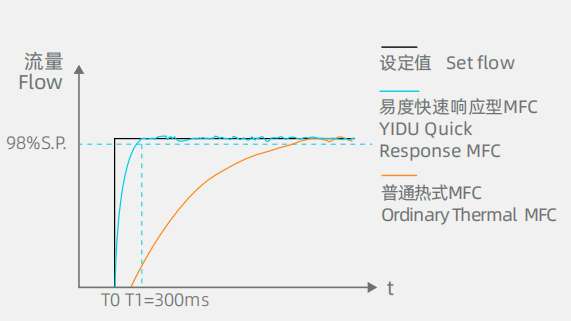

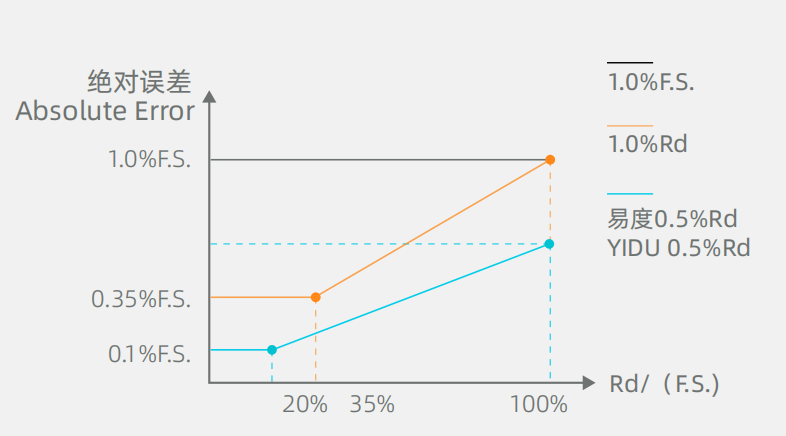

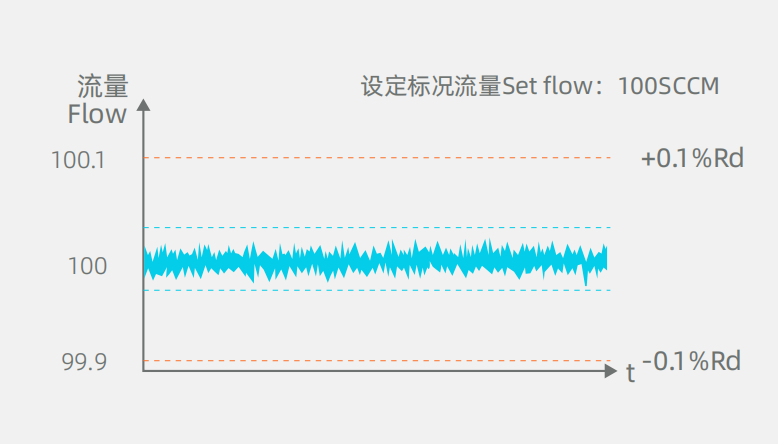

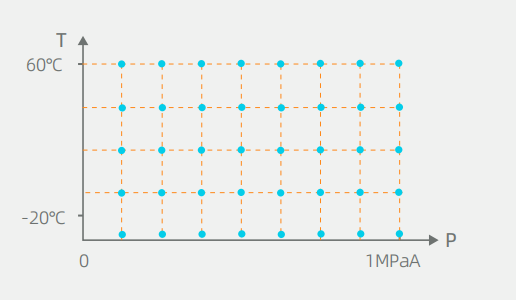

<Swipe Left/Right: High Accuracy / High Repeatability / Low Zero Drift / Fast Response Speed>

Advancing Towards Intelligence with Brain-Computer Interfaces

At the current stage, technological evolution is creating deeper intersections between differential pressure laminar flow MFCs and the future of BCIs:

· Intelligent Operation and Maintenance: Integrated digital interfaces (e.g., RS485, EtherCAT) support remote monitoring and predictive maintenance, aligning perfectly with the remote management needs of BCIs as intelligent medical devices.

· Breakthroughs in Nano-scale Flow: Advancements in processing technology are pushing the lower range limit below 0.1 SCCM, enabling the possibility of more minute neural interactions in the future.

Welcome to learn more about this application or discuss the fluid measurement and control challenges you face!

#Yidu #MFC #BrainComputerInterface #DomesticHighEndInstruments #PanSemiconductor

· end ·

// If you are interested in our application,

please scan the QR code to fill out the form //