2025-11

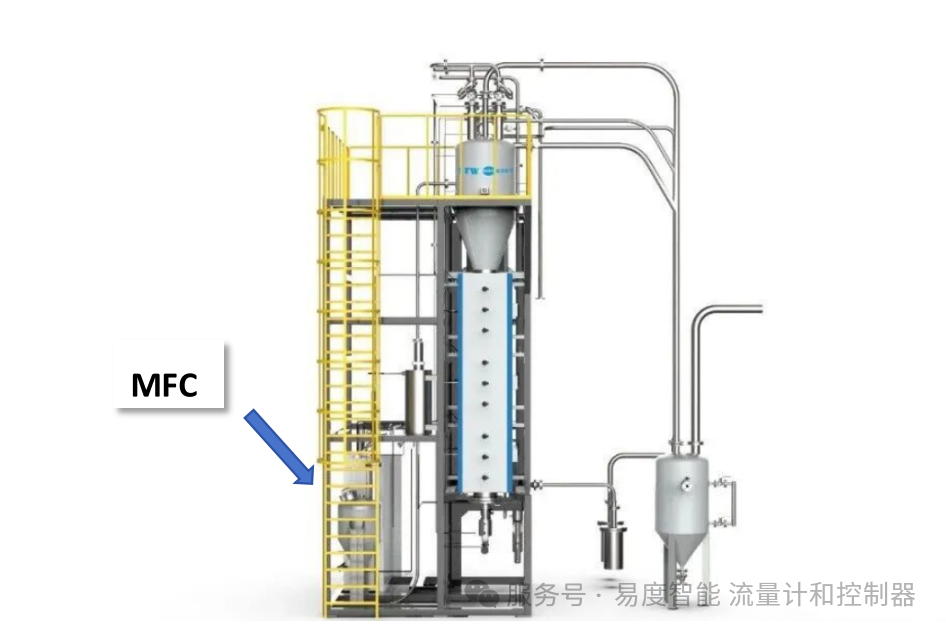

27A Crystallization-Resistant, Temperature-Immune MFC is Gaining Traction in Silicon-Carbon Anode Manufacturing

Laminar Flow Differential Pressure MFCs Precisely Overcome Challenges of Temperature Swings and Crystallization.

How can we achieve longer battery life for your phones and electric vehicles? The answer lies in "Silicon-Carbon Composite Anode Materials!" As the next-generation anode material for lithium-ion batteries, silicon-carbon composites have attracted significant industry attention due to their remarkably high theoretical specific capacity of 4200mAh/g.

However, their production via fluidized bed Chemical Vapor Deposition (CVD) processes has long been plagued by three major pain points for manufacturers:

Demanding Environmental Adaptability: Fluidized bed CVD equipment is often located outdoors. Annual temperature fluctuations exceeding 50°C cause severe measurement drift in thermal Mass Flow Controllers (MFCs).

Critical Contamination Resistance: During silane deposition, silicon dioxide crystals form and can adhere to the inner walls of thermal MFC capillaries. This alters the heat transfer characteristics, leading to inaccurate readings.

High Maintenance Burden: Frequent crystal contamination not only disrupts process stability but also significantly increases equipment maintenance frequency and costs.

Laminar Flow Differential Pressure MFCs Offer a Groundbreaking Solution

Core Technical Advantages:

The differential pressure sensing principle is based on the Hagen-Poiseuille law, calculating flow rate by measuring the pressure drop across a laminar flow element.

The innovative overall design eliminates capillary tubes. All process gas flows through the main channel, which features a straight, unobstructed flow path without sharp bends. This structural design inherently reduces sites for silicon dioxide adhesion. Even minor crystal formation does not disrupt the established laminar flow profile, allowing the MFC to maintain accurate flow measurement.

Performance Benefits of YIDU Laminar DP MFCs:

High accuracy of ±0.5% of set point.

Built-in database for over 70 gases, enabling instant gas switching without removal from the process line.

Rear-positioned valve design effectively isolates the controller from downstream pressure fluctuations.

Fast response time, reaching 98% of setpoint in under 700ms.

Real-time flow monitoring with millisecond-level updates.

Straight-through, large flow path design minimizes silicon dioxide buildup, significantly extending maintenance intervals and reducing total cost of ownership.

Delivering Tangible Customer Value:

Extended maintenance cycles, leading to substantial operational cost reduction.

Enhanced process stability, ensuring superior product consistency and quality.

Robust performance in harsh operating conditions, supporting reliable production ramp-up.

Meet Us at the 9th International Carbon Materials Conference!

Date: December 9-11, 2025

Location: Shanghai, China

YIDU will showcase its flagship products, including these advanced MFCs.

Booth Number: N1B45

We invite you to visit our booth for a deeper dive into this application or to discuss any fluid measurement and control challenges you are facing