2025-11

07Accurate control of flow rate MFC empowers CVD silicon carbon negative electrode process innovation

Silicon carbon negative electrode materials belong to the four main materials of lithium-ion batteries: positive electrode materials, negative electrode materials, electrolytes, and negative electrode materials in separators. They have a significant impact on the energy density (vehicle range), cycling performance (service life), charge discharge rate (fast charging efficiency), and low-temperature discharge performance (vehicle range degradation in low-temperature environments) of lithium-ion batteries.

Multi gas universal reduces customer inventory

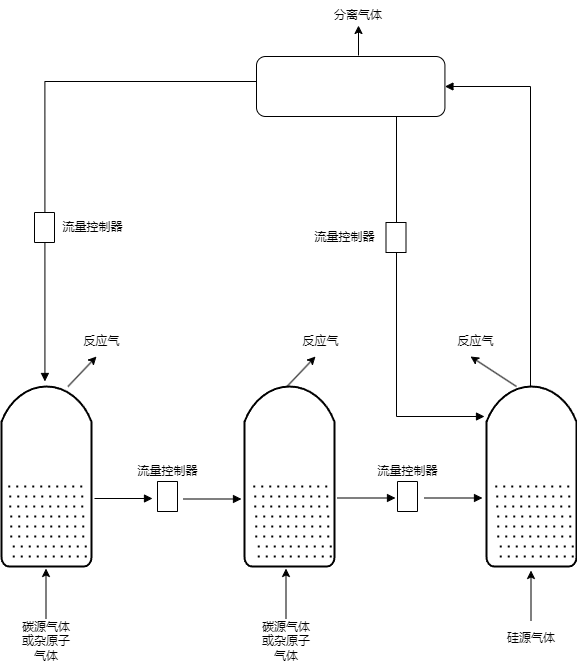

For CVD equipment, there are many types of gas control required, such as silane, acetylene, hydrogen, argon, oxygen, etc., and multi-channel collaborative control is also needed to achieve them; The thermal mass flow controller is based on thermal transfer, and each product needs to be calibrated with actual gas before leaving the factory, so it can only be applied to one gas in principle.

The principle of laminar flow distinguishes different media based on viscosity, which is a physical property parameter of gases. The viscosity of each gas is a constant value under specific working conditions. As long as the viscosity coefficient and algorithm are set properly, it is possible to directly switch the working fluid, which can be applied to multiple gases.

Regarding key processes such as the synthesis of nano silicon, decomposition of acetylene during vapor deposition, and formation of carbon coating layer. The EC series of high-precision quality flow controllers from YIDU, with its high accuracy (± 0.5% S.P.), high repeatability (± 0.1% Rd), corrosion resistance, excellent sealing performance, and long-term product stability, ensures process stability and material consistency, promotes material performance improve

ment (such as energy density and cycle life), and significantly improves production safety. Received unanimous praise from customers.

1. Specification and model EC450

2. Accuracy ± 0.5% S.P. (set value) (20% to 100% range) ± 0.1% F.S. (full range) (0.5% to 20% range)

3. Pressure drift Zero: ≤± 0.1% Rd/100kPa; Span: ≤± 0.1% Rd/100kPa (reference 100kPa (absolute pressure))

4. Temperature drift Zero: ≤± 0.02% F.S./℃; Span: ≤± 0.02% F.S./℃ (reference temperature 25 ℃)

5. Range: 0.1SCCM~20000SLPM

6. Repetitive accuracy ± 0.1% Rd (20%~100% F.S.) ± 0.02% F.S (0.5%~20% F.S.)

7. Scope of work: 0.5% to 100% F.S

8. Response time (T98) ≤ 300ms

Start preheating time: Ready to use without preheating upon startup

Let each microliter of gas accurately define the performance of silicon carbon anode! From laboratory to mass production, we safeguard process stability!

About YIDU Intelligence

Shaanxi Yid Intelligent Technology Co., Ltd. (referred to as "YIDU Intelligent") is the first domestic manufacturer of universal laminar flow mass flow meters and controllers. The company has been focusing on the research and development of high-precision laminar flow mass flow meters and controllers for more than ten years, helping users solve various fluid measurement and control problems. The company is committed to becoming a leading global supplier of laminar differential pressure flow measurement and control solutions. At present, a pre-sales and after-sales service system with Xi'an as the research and development center and radiating throughout the country is gradually forming.

Since its establishment, YIDU Intelligent has adhered to the entrepreneurial intention of "one small step for instruments, one big step for civilization", and is committed to the research and development of laminar differential pressure technology. The core R&D team is composed of several postdoctoral, doctoral, and master's students from Northwestern Polytechnical University, relying on the R&D team's aerospace professional background, and based on fluid mechanics, materials science, embedded hardware and software development and other majors. With more than ten years of independent research and development, YIDU Intelligent has accumulated profound technical experience in laminar differential pressure principle, especially in the field of microflow measurement and control. Currently, it has obtained more than 20 innovative patent technologies and dozens of authoritative certifications at home and abroad. For many years, the company has adhered to scientific research and development principles, starting from a formula and gradually developing high-performance products. And has obtained the highest technical certification (CPA) in China, making it the only known manufacturer of laminar flow mass flow meters and controllers certified by the Chinese Academy of Metrology. It is also the second high-tech enterprise in the world capable of producing universal laminar flow mass flow meters.