2021-12

24Comparison of Performance and Application of Laminar and Thermal Principle Gas Mass Flowmeters/Controllers

Gas microflow measurement and control has always been one of the important core technologies in high-end manufacturing, and the core sensors and control components in this core technology field are the gas mass flow meters and gas mass flow controllers that we will focus on discussing today.

What are gas mass flow meters and gas mass flow controllers used for?

Of course, as the name suggests, it is used to measure and control gas flow. The gas here does not refer to natural gas at home, or gas used in traditional energy and chemical enterprises, power plants, etc. In these scenarios, the measured and controlled gas flow rate and corresponding pipe diameter are generally relatively large, with gas flow rates mostly above 15m ³/hour, and corresponding pipe diameters ranging from 15mm to 3000mm (or even larger).

传统行业的流量计

The gas mass flow meter and gas mass flow controller we are discussing here refer to those suitable for small and micro flow rates (from 0.000001m ³/hour to 300m ³/hour, corresponding to pipe diameters ranging from diameter)

Sensors and devices for gas measurement and control ranging from 3mm to 65mm require a very small volume (usually the size of a palm) and precise measurement and control (with repeatability accuracy better than 0.2%),

And it needs to withstand the influence of environmental temperature and pressure, as well as different gas working media. Currently, gas mass flow meters and gas mass flow controllers that meet the above requirements mainly have two principles

The products are:

Gas mass flowmeter and controller based on laminar flow principle

Gas mass flowmeter and controller based on thermal principle

层流原理与热式原理气体质量流量计与气体质量流量控制器应用于哪些领域?

I want to focus on this issue. Almost all high-tech industries or high-end manufacturing industries that you can think of have their presence wherever precise gas measurement and control is needed. Due to space constraints

Limit, let me briefly explain first and give a few more examples. These products that we often use in our daily lives have their presence, such as mobile phones, computers, wristbands AR/VR、 TV, cars, medicine, beer

Alcohol, air conditioning, watches, gas stoves, batteries, jewelry, and more.

The high-end and cutting-edge technology fields that are not often encountered in daily life also have their applications. For example, satellite manufacturing, graphene production, synthetic diamonds (diamond ring grade), nuclear power plants, nuclear

Fusion reactors, optical fibers, quantum computers, chip manufacturing, anti-cancer drugs and gene drugs, ventilators and anesthesia machines, online environmental monitoring systems, air pollution prevention and control equipment, electric vehicles

Production of fuel cells, solar panels, and so on.

So many fields and products have their presence, can you give us a more specific understanding of where they are actually used? Shouyi Ge spent a lot of homework time and consulted a large number of professionals

Let's take a closer look through two examples.

Let's take the most commonly used and jokingly referred to as "human organs" mobile phones as an example. First, let's take a look at the casing of a phone. Generally, phone casings are delicate, smooth, and have high wear resistance and hardness. How is this surface made

Did you come? The specific process is very complex and will not be elaborated here, but the most critical process needs to be completed in a device called a vacuum coating machine, which involves introducing ionized gas and the process in a vacuum environment

By using ionized plasma to collide with the target material, a special thin film is deposited on our phone case at the microscopic scale. It is this protective film that gives our phones a smooth texture and durability

Grinding performance. And this vacuum coating machine is equipped with a large number of gas mass flow controllers, which are used to finely control the amount of ionized gas and process gas entering the vacuum coating machine, with a rough flow rate of 5

00SCCM。

The second important function of a phone case is waterproofing, as there are a large number of electronic components inside the phone, making waterproof performance particularly important. The early waterproof performance of mobile phones was not very good, and it was easy to be careless

Easy to enter water and be damaged. With iterative progress, current smartphones have become highly waterproof. But how to verify whether the waterproof performance meets the standard? We need a more powerful air tightness tester.

CTS positive pressure air tightness tester

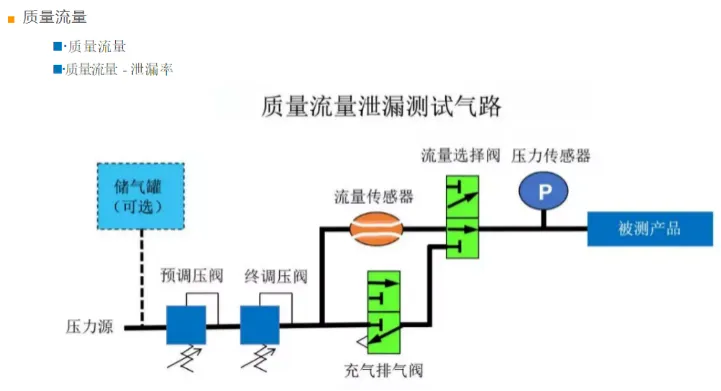

Apple's iPhone and other devices extensively use CTS's airtightness tester for waterproof testing, which has high sensitivity and fast testing efficiency. The flow type airtightness detector used by CTS company is a more advanced detection method compared to pressure and differential leak detectors. The core component is the micro flow gas mass flowmeter (as shown in the schematic above), with a flow range of 0.001ml/min to 2ml/min (or SCCM).

正压式气密性检测仪的原理图

Schematic diagram of ATC negative pressure airtightness tester

There is currently no reliable supplier for this advanced airtightness tester in China, and it is almost monopolized by two American companies. One of the core reasons is that it can produce high-performance microfluidics globally

There are very few gas mass flow meters available.

Before the launch of iPhone 8, Apple CEO Tim Cook personally visited CTS headquarters in Cincinnati, Ohio, USA to thank them for their air tightness testing equipment, which effectively ensured the quality of Apple's products,

This shows its importance!